If size matters then the large frame three-point linkage is for you. Designed as an alternative to a trailed sprayer with tanks sizes ranging from 1500L through to 2000L and three different boom styles from 15m to 28m.

The versatility of the large frame 3PL has meant it has found homes in cereal, cotton and horticulture areas right across Australia. All models are fully configurable to suit your individual needs.

Typical uses

| Features | 1500L | 1800L | 2000L |

|---|---|---|---|

| Broadacre spraying | ✓ | ✓ | ✓ |

| Rowcrop spraying | ✓ | ✓ | ✓ |

| Vegetable spraying | ✓ | ✓ | ✓ |

| Horticultural spraying | ✓ | ✓ | ✓ |

| Weed control | ✓ | ✓ | ✓ |

| Pest control | ✓ | ✓ | ✓ |

| Industrial spraying | ✓ | ✓ | ✓ |

| Municipal spraying | ✓ | ✓ | ✓ |

| Contracting | ✓ | ✓ | ✓ |

| Specialised cleaning | |||

| Inoculant spraying | |||

| Fertiliser application | ✓ | ✓ | ✓ |

| Fire Fighting | |||

| Water transfer | |||

| Irrigation | |||

| Washdown |

- The frame utilizes thick walled Australian made steel to create an extremely strong structure, essential when fitting wider booms. The key to its strength is the combination of square and rectangle hollow sections (SHS & RHS) and precision laser cut plates placed in strategic locations. The frame is also very narrow which helps to keep the boom as close as possible to the tractor wheels for better weight distribution. The tractor pick up points are designed to suit a category three linkage equipment. Retractable support legs provide stability when the sprayer is disconnected from the tractor.

- Goldacres four stage paint process. 1. Grit blasting which cleans and prepares the steel surface for the ultimate paint adhesion. 2. High build primer / filler flattens out the surface and is key to giving the top coat not only an optimum substrate to adhere to but that smooth “wet” look. 3. Wet top coat using the highest quality Australian made paint. Specially formulated for Goldacres the top coat provides a finish which has excellent mar resistance (the resistance to abrasive action like scratching) and also a very high tolerance to aggressive chemicals. 4.High temperature baking which cures the paint

- Australian made rotationally moulded thick wall UV stable tank with an extra deep centre sump design. Smooth internal wall aids rinsing and decontamination. The tanks are available in 1500, 1800 and 2000L capacities.

- 100L saddle style rinse tank mounted to the top of the main product tank. The rinse tank can be used to flush out the pump and boom lines at the end of the spray job whilst still in the field.

- Tank level sight tubes (main and rinse tank) allows the operator to visually check volumes from inside the tractor.

- High volume high pressure (170 l/min 20 bar) three piston diaphragm pump with 540 rpm PTO shaft provides smooth consistent water flow to the boom. If more flow is required then this pump can be upgraded to a 260 l/min unit.

- A pump suction filter with three way ball valve allows the operator to switch between drawing from the main tank and the rinse tank. The off position also allows the strainer to be removed and cleaned even when the sprayer tank is full.

- Twin pressure line filters greatly reduce the chances of nozzle blockages. The first filter is a coarse mesh while the second is finer.

- Venturi agitator fitted to the tank greatly improves the consistency of the tank mix over the course of the spray job.

- Chemical venturi probe is used to draw neat chemicals into the main tank. This type of chemical induction means that at no stage does neat chemical come into contact with the pump, which could cause corrosion problems.

- Plumbed from the external filling point the internal tank rinse nozzle with rotating head quickly and easily decontaminates the inside of the tank.

- Top mounted bottom fill allows the water to be pumped in through the top of the tank and down to the bottom. This method reducing foaming and also reduces the risk of contaminating the water source if the transfer pump stops unexpectedly.

- All spray hoses are constructed using a Nitrile liner. This liner helps resist the effects of the most aggressive of chemicals from damaging the hose.

- Electric section and pressure regulation control is fitted for easy in cab adjustment. While an external control station is used to operate auxiliary functions like chemical transfer and agitating. An adjustable pressure regulator valve is fitted to set the maximum system pressure.

Choice of three different booms. Refer to booms section for more information.

Induction hopper. The 40L capacity chemical induction hopper is an integrated chemical transfer system that allows liquids, granular and powdered products to be measured and transferred into the main tank. The hopper has both drum and internal rinsing capabilities. The high flow venturi is mounted at the base of the hopper which draws chemical into the water stream at that point, minimising the chance of blockages.

Raven SCS450 and SCS4400 automatic rate controllers adjust the flow rate according to speed to maintain a consistent spray application rate. Features include up to five boom sections control on the SCS450 and seven section on SCS4400, pre-set application rates plus a manual mode, display of ground speed and flow rate plus many other counters.

Raven SCS450 and SCS4400 automatic rate controllers adjust the flow rate according to speed to maintain a consistent spray application rate. Features include up to five boom sections control on the SCS450 and seven section on SCS4400, pre-set application rates plus a manual mode, display of ground speed and flow rate plus many other counters.

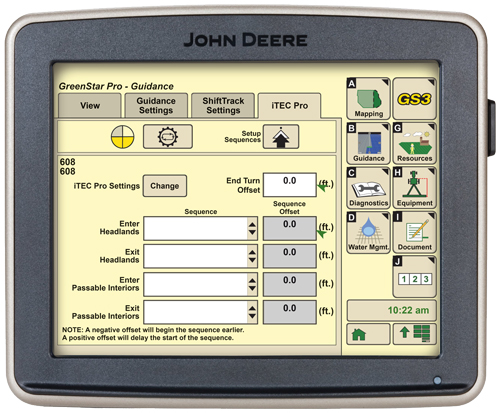

ISO BUS control system. This system allows the sprayer to be controlled using a virtual terminal (VT) which might also be used for other duties, like mapping or tractor steering. The brains of the system, called a node is mounted to the sprayer, this node does all the control work. The VT simply displays and communicates all the information to the operator. Can control up to ten boom sections.

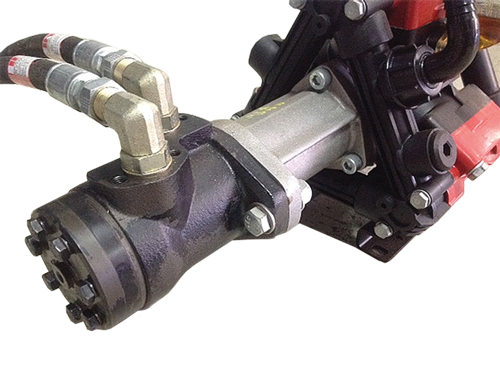

Do away with the pto shaft with a hydraulic drive kit. Neatly adapts to the existing pump and is run directly from the tractor remotes. When used in conjunction with the Raven SCS450 then pump rpm can also be monitored. If a non-Raven monitor is fitted then Goldacres can supply a separate pump rpm monitor.

An electric over hydraulic manifold can be fitted to the sprayer if your tractor does not have enough hydraulic remotes. The manifold is fitted with flow control valves and load holding checks where required and can be configured to control up to six functions.

45L exacta foam marker can be installed as a simple, low cost alternative to a GPS system. The exacta foam marker uses separate water and detergent tanks. Final mixing with the liquid and air is done out at the boom ends with a foam generator to produce high volumes of dense foam. Available in single or double-sided.

Ultrasonic boom height control systems can be fitted to the TriTech series of booms. A combination of ultrasonic sensors mounted on the boom wings and onboard computers adjust the wing tilt hydraulic cylinders to help maintain a consistent boom height above the target. Perfect for use in.

| Features | Delta booms | TriTech booms | Krono booms |

|---|---|---|---|

| 1500L main product tank | Option | Option | Option |

| 1800L main product tank | Option | Option | Option |

| 2000L main product tank | Option | Option | Option |

| 170 l/min diaphragm pump | Std | Std | Std |

| 260 l/min diaphragm pump | Option | Option | Option |

| Hydraulic drive upgrade for pumps | Option | Option | Option |

| 12m boom | N/A | N/A | Option |

| 15m boom | Option | N/A | Option |

| 18m boom | Option | N/A | N/A |

| 21m boom | Option | N/A | N/A |

| 24m boom | Option | Option | N/A |

| 28m boom | N/A | Option | N/A |

| Trijet nozzle bodies | Option | Option | Option |

| Fenceline jet single sided | Option | Option | Option |

| Fenceline jet double sided | Option | Option | Option |

| Fenceline jet single sided electric | Option | Option | Option |

| Fenceline jet double sided electric | Option | Option | Option |

| Foam marker exacta 45L single sided | Option | Option | Option |

| Foam marker exacta 45L double sided | Option | Option | Option |

| Boom plumbed in 3 sections | Std | Std | Std |

| Boom plumbed in 4 sections | Option | Option | Option |

| Boom plumbed in 5 sections | Option | Option | Option |

| Boom plumbed in 6 sections (SCS4400 & ISO BUS systems only) | Option | Option | Option |

| Boom plumbed in 7 sections (SCS4400 & ISO BUS systems only) | Option | Option | Option |

| Boom plumbed in 8 sections (ISO BUS systems only) | Option | Option | Option |

| Boom plumbed in 9 sections (ISO BUS systems only) | Option | Option | Option |

| Boom plumbed in 10 sections (ISO BUS systems only) | Option | Option | Option |

| Norac boom height control 3 sensor | N/A | Option | N/A |

| Bi-fold | N/A | Option | N/A |

| 3D breakaway boom ends | Option | Std | N/A |

| Boom end protectors | Option | Std | N/A |

| Individual boom wing tilt | Option | Option | Std |

| Boom slant kit | N/A | N/A | Std – 15m Option – 12m |

| Electric over hydraulic spool valves | Option | Option | Option |

| Induction hopper 40L | Option | Option | Option |

| Separate pump RPM monitor (for when non raven controller fitted) | Option | Option | Option |

| Electric section control and pressure regulation | Std | Std | Std |

| Automatic rate control Raven SCS450 (5 sections max) | Option | Option | Option |

| Automatic rate control Raven SCS4400 (7 section max) | Option | Option | Option |

| ISO BUS automatic rate control system | Option | Option | Option |

Reviews

There are no reviews yet.