Arguably the biggest advancement to the new model is the adaption of Goldacres own in-house developed G-Hub sprayer control system.

Goldacres has raised the bar in the trailing sprayer market with the all-new Prairie Pro Series 2.

The Prairie Pro has been our flagship trailing model since its release 2015, however, with farming practices changing in a direction that requires higher accuracy, less wastage, and getting more done a rethink of the range was required.

The philosophy behind the new model was to create a trailing sprayer that shared the same filling and application technology from the recently released G6 Crop Cruiser Series 2.

Headlining the Series 2 range is a capacity-topping 10,000-litre version with a choice of the 36m RivX boom or the tri-folding 48m TriTech V Series boom. Totally redesigned 5000, 6500, and 8500 litres models are also available with boom sizes from 24-36m with the TriTech RivX boom or 48m TriTech V series boom on the 8500L.

The new Prairie Pro Series 2 features a totally new chassis and adjustable height pull to adapt to different tractor drawbars. The pull is a narrow design with the pump located to the right-hand side chassis and the large rinse tank fitted under the sprayer platform.

A new higher platform and boom rest design radically cleans up the appearance of the machine whilst making access to the tank much easier.

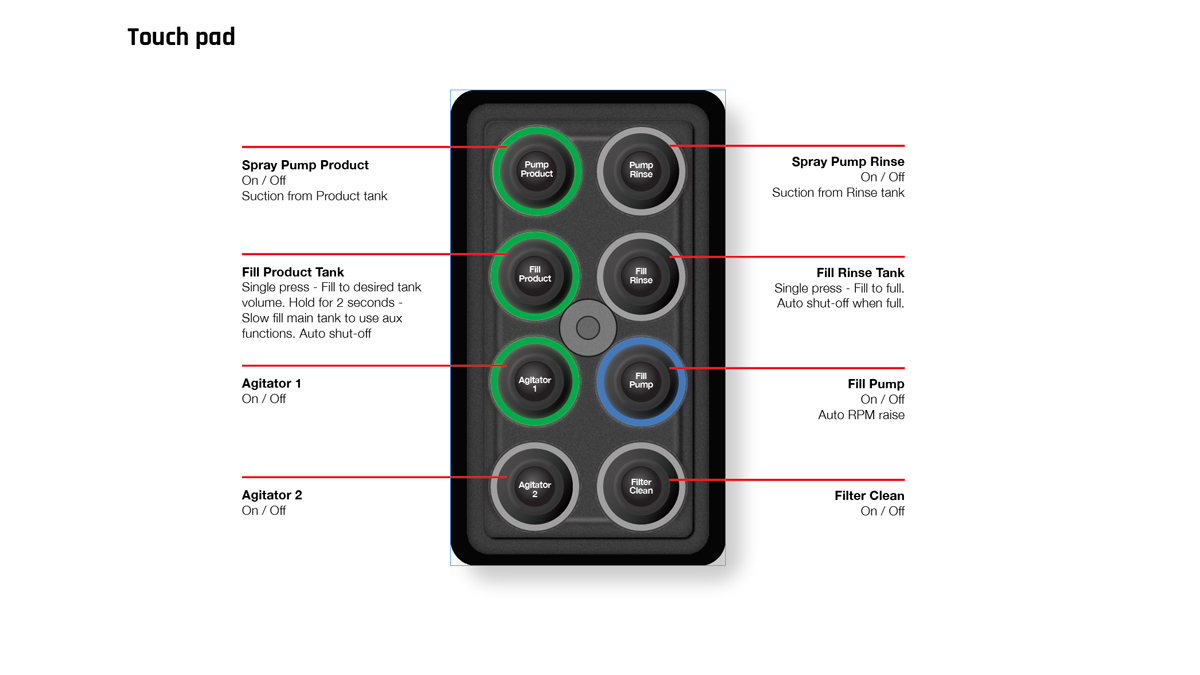

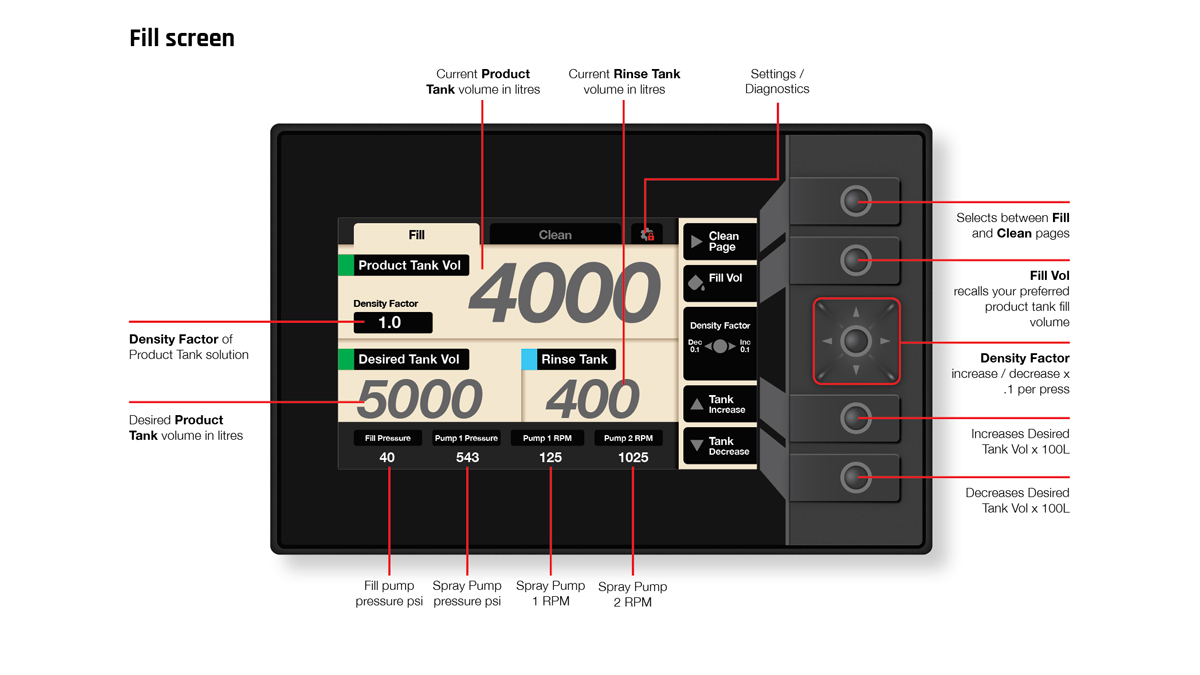

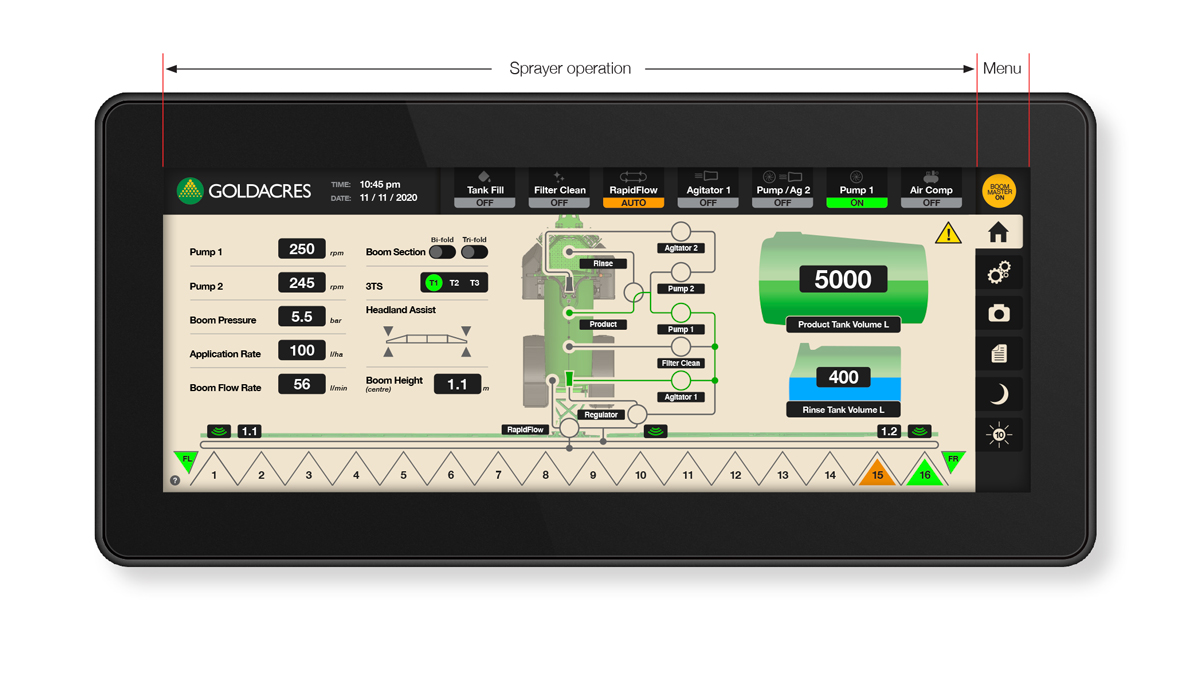

Arguably the biggest advancement to the new model is the adaption of Goldacres own in-house developed G-Hub sprayer control system. Comprising of a full colour 5” screen and keypad at the fill station and an optional 12” colour touch screen inside the tractor cabin, the system allows all functions to be quickly operated with a minimum of fuss. One of the key features of the G-Hub is the ability to enter a tank fill volume and the system does the rest, shutting off the pump and fill valves once the fill volume is met.

All sprayer plumbing is designed to allow for higher fill and application rates. Fitted with an IsoBus controller and boom plumbing in either 10 or 16 sections with the Goldacres RapidFire nozzle switching and RapidFlow boom recirculation as standard.

Read on for more exciting details on these range-topping trailing models:

Simply enter the desired tank volume, connect the fill hose and the G-Hub system will automatically shut off when fill volume is achieved.

Featuring a full colour 5” screen and button panel to control all fill and clean functions with the push of a button.

The screen and button panel are mounted next to the storage compartment but under the door for protection when spraying. In addition, the G-Hub system also manages the liquid control valves which operate chemical induction, agitation, and cleaning functions.

The PLC is located inside the storage compartment and provides diagnostic lights to assist troubleshooting.

If the optional in-cabin screen is not fitted then basic system diagnosis can be performed on this screen. To enter the diagnosis section press and hold the clean page button for 5 seconds.

The Prairie Pro Series 2 now features the new electronic control system referred to as G-Hub.

Whilst visibly similar the software has been specifically tailored to suit the requirements of the trailed sprayer and will be offered in two levels of sophistication with the base version omitting the 12” cabin display and rearview camera.

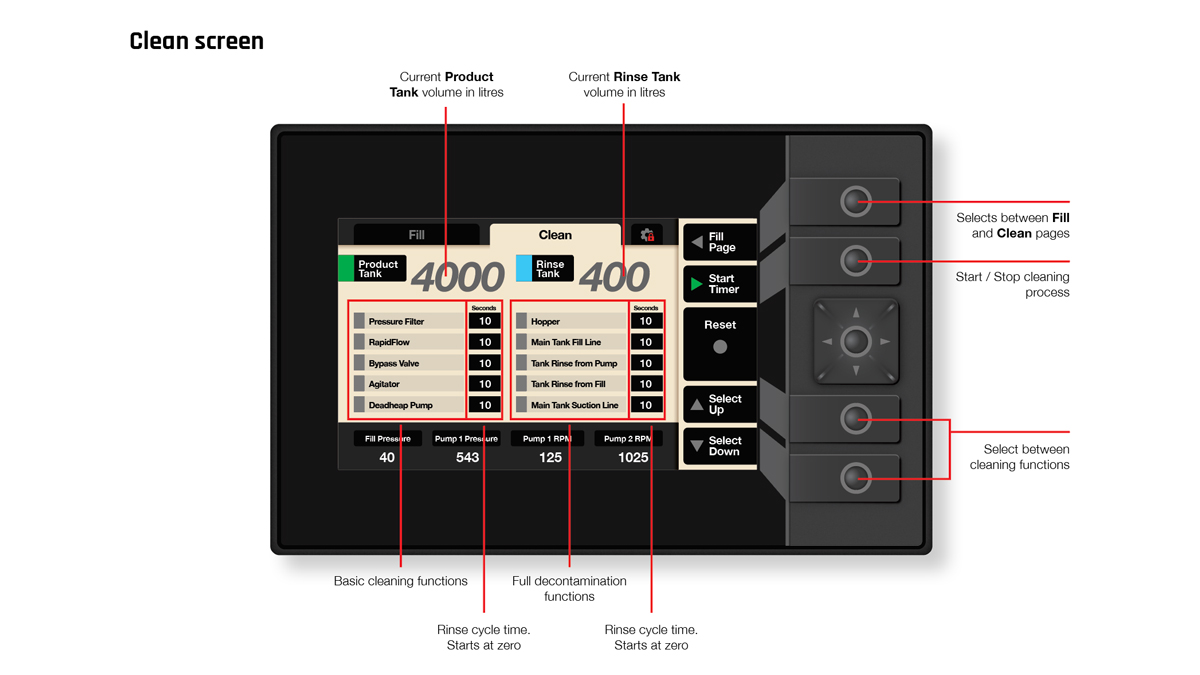

The G-Hub system comprises of an optional cabin display, external display, PLC (programmable logic controller), I/O modules, sensors and switches control and monitor all critical machine functions and packages it all into one easy to use fully integrated system.

The G-Hub also operates seamlessly with all leading steering and mapping providers using the ISO BUS protocol.

On-board diagnostics allows operators to quickly pinpoint problems without the need for laptops, specialised service tools, or internet connections, thus minimising downtime. For systems without the optional 12” cabin display the diagnostics features are reduced and must be performed on the external display. For more in-depth diagnostics the 12” screen must be used. It is recommended that a 12” screen be available to the service department.

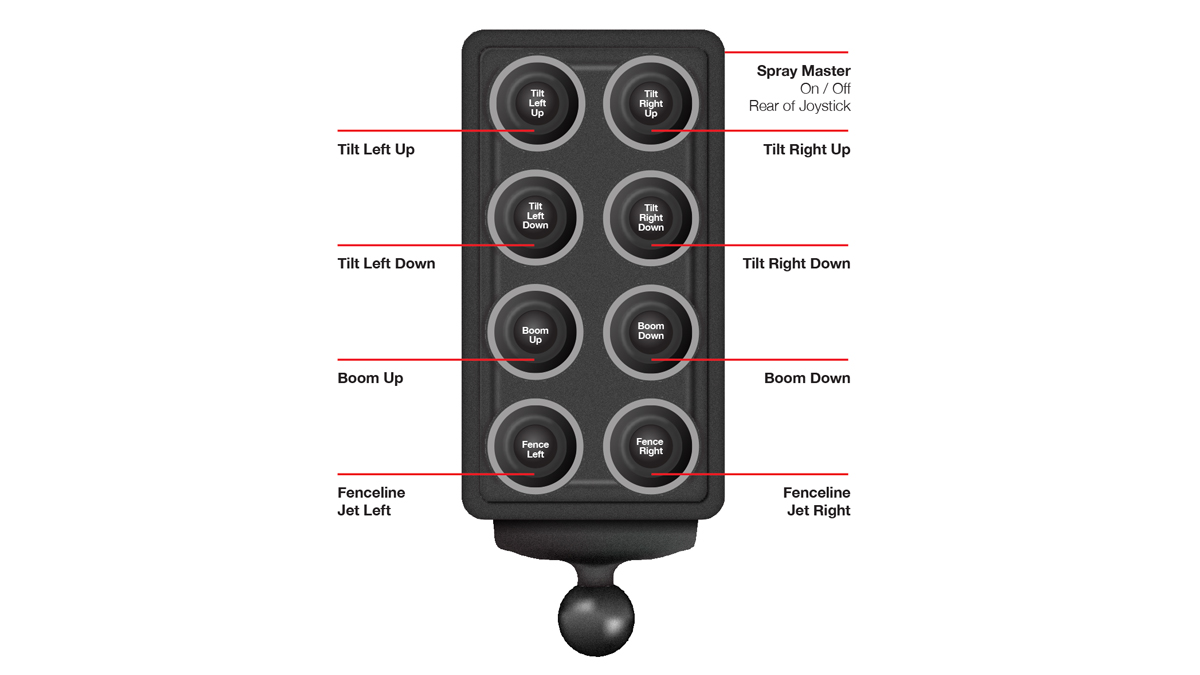

Joystick keypad

The joystick features a RAM mount® to allow flexible mounting options to the tractor side console. In addition, the 8 button keypad can be removed and remote mounted within the tractor console. As there are so many makes and models of tractors to work with this was felt the best solution to make mounting integration as simple as possible. The joystick will be supplied with a separate universal mounting bracket.

The spray master switch at the rear can be bypassed and a footswitch or similar installed.

Auxiliary keypad

The auxiliary keypad is used to operate many of the sprayer control functions and boom folding activities. Both keypads feature backlighting and operating status. For sprayers not fitted with the optional 12” cabin display, these function lights also provide some level of warnings via flashing or different colour lights.

Optional 12” cabin display

Low profile 12” full-colour touch display allows the user to quickly see and operate all the important sprayer functions. The display provides the perfect aspect ratio to clearly display important information as well as large button areas such as the boom sections where the entire screen width is utilised.

12” Cabin display features

- Machine information including product and rinse tank levels, pump(s) RMP, boom height, RCM rate controller data, XRT data

- Easily adjust machine settings including pump speed and auto-folding settings

- Extended control of boom plumbing functions including boom prime and filter cleaning modes

- Warnings and info messages related to sprayer operation

- Advanced filling functionality

- Full machine diagnostics

- Ability to turn air compressor off

- Virtual boom switch box

- See and set pump service hours

- Reverse camera

- Audio feedback

- Built-in user manual

- Virtual controls in case of keypad failure

Connection points.

- 3” Camlock “clean” connection point using an optional onboard fill pump to transfer clean water throughout the sprayer at rates of up to 1150 l/min.

- 3” Camlock “dirty” connection point for pre-mixed water and chemical for transfer directly into the main product tank.

- Both connection points allow accurate measured volumes to be transferred into the main product tank.

- 1” Camlock connection point for neat chemical transfer using the onboard chemical transfer pump.

- 1” Camlock connection point which provides a pressure source for sprayer wash down purposes.

- Micromatic socket rinse coupler.

Chemical transfer pump (optional)

Neat chemical transfer is now done using a Graco pneumatic twin diaphragm high capacity pump (optional). The pump features large-diameter diaphragms to create large amounts of suction, ideal for high viscosity chemicals. The neat chemical can be delivered directly to the product tank or diverted to the chemical induction hopper where it can be measured and then transferred to the product tank. Tests have shown 40 l/min of high viscosity chemicals can be transferred.

Fill pump (optional)

A Hypro 3” transfer pump can now be fitted. This pump combined with high flow plumbing provides flow rates of up to 1150 l/min. Mounted to the pump outlet is a pressure transducer and electric 3” ball valve which is used by the G-Hub system to control both the fill rate and tank level soft shut off.

Storage locker

- Lockable storage locker with internal shelf. Holder for soap bottle plus and internal light for nighttime use.

- Location for G-Hub external display which is used for all external filling and rinsing functions.

Induction hopper

- 60L capacity

- Chemical transfer rates of up to 150 l/min. (depend on chemical viscosity)

- Chemical induction can also be done via the probe directly into the hopper base

- Foot-operated lower shutoff valve.

- Wash down gun powered by separate 12-volt pump using water from rinse tank.

Today’s sprayers are full of bells and whistles which makes spraying a whole lot easier, comfortable and efficient, but it’s easy to forget what the end goal is. Precise chemical application.

Boom control can be the difference between a good spray result, and no result at all. Goldacres understand this and it is why all our sprayer designs are centred around the boom first and foremost.

Why do Goldacres booms ride so well?

Goldacres pioneered the use of lightweight aluminium in the outer boom wings over two decades ago. The philosophy was and still is today that mass on a boom is fine so long as it is as close to the centre as possible. Reduced mass on the boom extremities reduces boom forces in both yaw and roll. This combined with the unique boom suspension results in a very stable boom ride, regardless of the terrain.

TriTech booms are contour following, meaning that the boom level will be referenced to the sprayer chassis and not purely on gravity such as a pendulum boom. This allows the sprayer to transverse the sides of hills and contours whilst keeping the boom level to the ground at all times. This results in placing the nozzle at the optimum height above the target.

Strength, Stability, Reliability & Control.

The TriTech boom range is designed for operators who demand the utmost performance, reliability and control. Time and time again the TriTech boom has been named “No.1 for boom stability”* which at the end of the day, results in a superior spray result.

Features such as hydraulic yaw which precisely controls the forwards and backwards movement of the boom wings to minimise the under and over applying of chemical are now standard on all widths.

The strategically placed centre section suspension links help isolate the sprayer chassis movement over rough terrain. Combined with the tuned damping characteristics allows precise roll control enabling an optimal and consistent nozzle height to be maintained, even without the use of electronic height control systems.**

All TriTech booms are constructed using lightweight trussing techniques, which allows for a stronger design without weight, the enemy of boom agility.

The No 1 boom now performs even better. The 24-36m Tritech RivX boom.

Instantly recognisable with a structural riveted outer boom wing, bright yellow boom tips and a hydraulic fold mechanism. The TriTech RivX boom lifts the standard for spray boom construction and performance.

The outer wings are aluminium and feature no welding. Thin mild steel plates are glued and riveted to the aluminium to produce a very strong truss without any heat effected aluminium areas. The boom inner and outer wings are fully symmetrical meaning left and right are interchangeable.

The fold system uses hydraulics and links but, unlike most other booms the hydraulic fold cylinder is fully retracted when the boom is fully open, this is when the hydraulic cylinder is at its strongest position and there is no chance of bending a cylinder rod. In addition to the hydraulic folding, the mechanism includes a hydraulic breakaway system in the event of a collision with an object.

Bi-fold is now a standard feature of this design.

Booms also have an auto fold system which is controlled through the G-Hub system.

Centre section

The boom centre section for the 24-36m booms has been lifted directly from the 48m design. This new centre section no longer uses the tilt arm design on the outgoing Pro, instead, the boom is connected to the centre using a high strength lower pivot arm which supports the boom in both torsional and lateral directions. The top of the boom is connected by the tilt cylinder, this connection system provides a lot stronger link between the inner boom and centre section folding mechanism.

Boom inners

The inner boom wings are all new and feature a single 100 x 50mm top cord and twin 50 x 50mm lower cords. A key design difference with this boom is the symmetrical construction technique. Left and right booms are identical which allows for lower inventory to be kept at a Goldacres and dealership level. At the outer wing fold point, the bolt-on and shimming pivot points have been replaced with adjustable spherical joints allowing easy boom adjustment. Hydraulic flip-down latches hold the outer wing in place once folded.

Boom outers

The RivX outer boom wings are constructed using a combination of thin gauge mild steel connection plates, high strength industrial steel rivets and adhesives, and structural grade aluminium profiles. The truss design is a reverse of the current model with the twin cords on the bottom (which are also 60mm wider apart) and a single 100 x 50mm cord on the top.

Hydraulic wing fold

In addition to the hydraulic folding, the mechanism includes a hydraulic breakaway system in the event of a collision with an object. This allows adjustable holding force with fully adjustable return speed.

Boom breakaway

The new breakaway now incorporates the protection frame. The nozzles, lights and fence line nozzle are fully protected by this new design. Breakaway section is also fully riveted and allows for a transport width on 24-36m booms of under 3500mm.

Boom plumbing

Boom plumbing has been increased from ¾” to 1” for both higher application rates and to also reduce pressure drop along the length of the boom. The boom lines and nozzle bodies are also mounted below the main structure of the boom and protected by a replaceable protection bar. By placing the nozzles under the main structure any spacing or configuration can be achieved and all nozzles are in perfect alignment.

Auto boom fold

Booms feature an auto fold system which is set up through the G-Hub system. Push boom fold button on the console to raise, auto level and fold-in. Lowering the boom onto the fold rest is still manual and will stop at the preset height. The main boom lift suspension accumulator will be locked out.

Remote grease nipple bank

4 x 6 nipple banks located on the upper paralift arm and rear of centre section are fitted standard, greasing the centre and lift pivot points.

Blue Lights

Blue lights are now fitted to all booms as standard. Blue lights enable the operator to easily see the spray pattern at night.

Massive productivity gains now available with the fitment of the 48m tri-fold boom.

Both the 8500L and 10,000L models can have the option to fit the 48m TriTech V boom. The chassis and connection points have been specifically reinforced to cater for the higher loads that the wider boom places on it.

Wider booms = greater productivity.

If we compare a 36m boom to a 48m we can see potentially 33% increase in productivity (depending on application rate)

- 36m boom at 20km/hr = 72ha/hr.

- 48m boom at 20km/hr = 96ha/hr.

48m features and benefits

- Outer wings feature a unique hydraulic break back and break forward function to help fight the forces of yaw while also providing security in the chance of a boom collision.

- Inner wings feature forward and rearward hydraulic dampening in conjunction with full yaw control.

- While using the boom in the folded 20m position the inner wing features a hydraulic latch to secure the outer and inner wing for increased boom rigidity and longevity.

- Single spray bar puts all spray nozzles in perfect alignment, allowing virtually any nozzle combination or configuration to be mounted on the boom.

- 1” poly tube plumbing for reduced pressure drop resulting in more even nozzle flow rates.

- Boom construction comprises of mild steel inner wings with aluminium used for the middle, outer and breakaway sections. This provides strength and durability where needed and weight savings as required. In fact this boom is comparable in weight to some other all aluminium booms on the market.

- The boom truss structure is significantly deeper and wider than our other width booms. This reduces cord stresses which improves overall longevity.

- Upgraded design of the aluminium sections now gives even improved strength. Dogleg shape on middle wing now replaced with a tapered chord to minimize stress points. Outer wing now folds up on an angle to provide the required clearance.

Spray widths

Three working spray widths can be achieved;

20m – mid section folded back.

36m – outer section folded back.

48m – all open.

Boom stability is only part of the chemical application story, optimum droplet sizing, pressure, nozzle flow rate and spray uniformity across the boom width are all critical to accurate chemical application

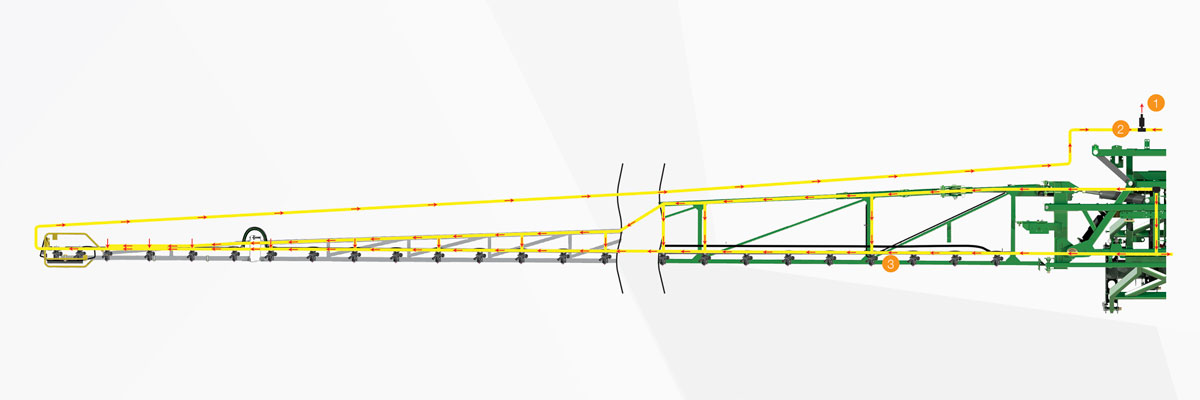

RapidFlow – Boom Recirculation* allows the sprayer boom lines to be fully primed without spraying a single drop. This reduces wastage at the start of a tank load or when switching chemicals. RapidFlow can also be used to thoroughly flush out the boom lines without the need to physically spray on the ground.

- Bank to main tank

- Electric ball valve

- Nozzle body with RapidFire

*RapidFire is not compatible with Direct Chemical Injection (DCI)

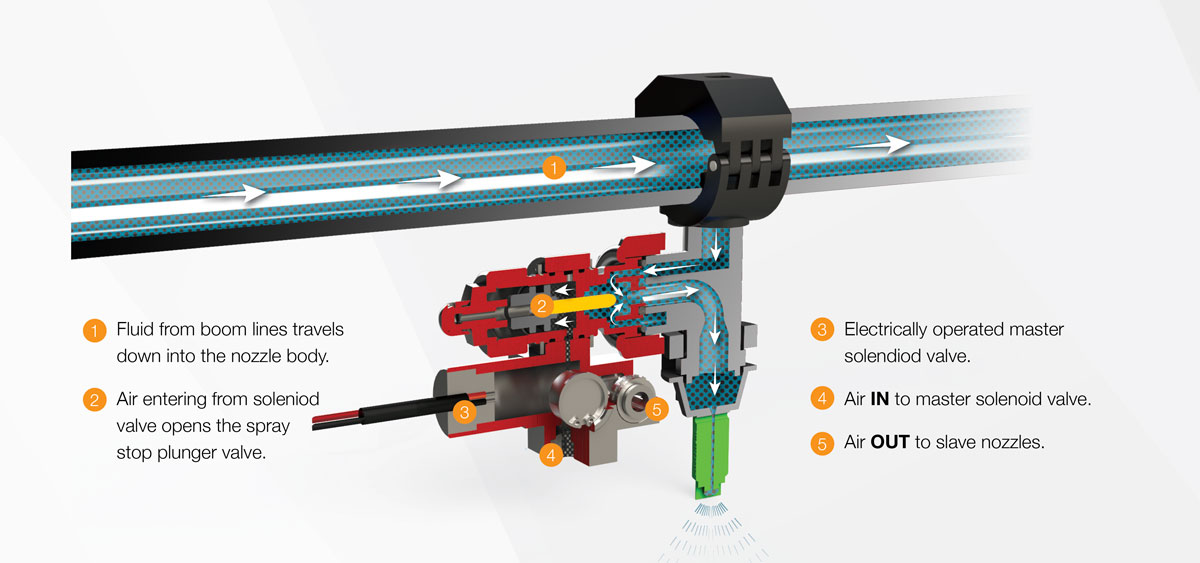

Over the last several years there has been a greater shift to precision farming technologies, such as auto steering and automatic boom section control. Both of these technologies are aimed at reducing spray overlaps and unsprayed areas, the former potentially causing crop burning and overuse of chemical. Depending on the field size and shape the wastage can be quite substantial. Goldacres have developed these practices further by introducing RapidFire air controlled nozzle shut off capability.

Traditional systems use motorised boom section valves to control water flow to the nozzles. Wider booms in conjunction with an increased number of spray sections means a substantial amount of plumbing is required, thus increasing the delay in spray on and off times. In addition, the further the nozzle is from the centre of the boom the longer the delay becomes. RapidFire overcomes these problems by putting the switching capability right at the nozzle.

Small airlines at each nozzle switch the flow on and off in a fraction of a second, and more evenly across the boom width. Boom line plumbing is also greatly reduced, which quickens line priming and flushing as well as simplifies plumbing.

Nozzle technology has advanced in leaps and bounds over the years and a strong emphasis on drift control has influenced many nozzle designs, including air induction (AI) technology

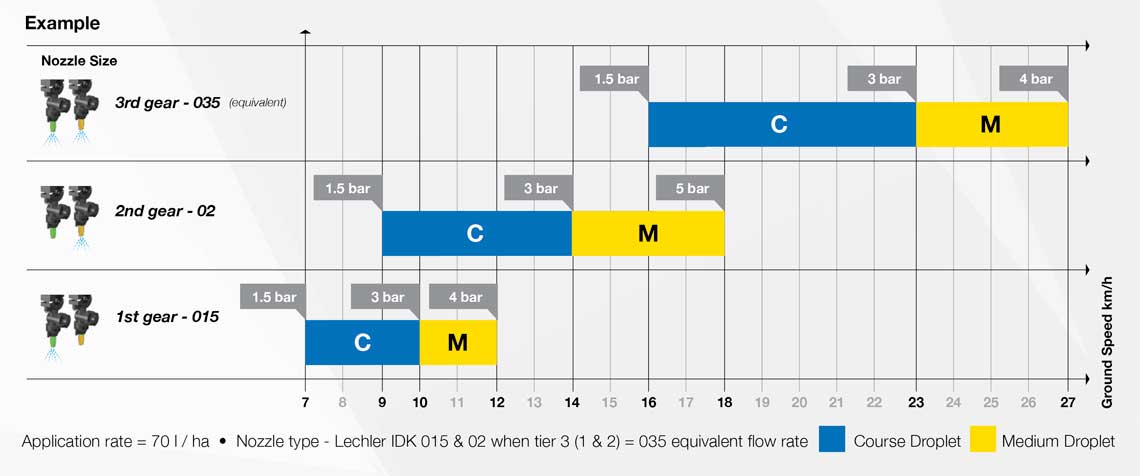

The spray nozzles operating pressure range & size determine the application rate and speed band at which the driver must adhere to. This band is usually quite narrow. Goldacres offer a 3 tier system (3TS) which effectively gives the driver a much wider operating band whilst still maintaining optimum droplet size.

The 3TS system effectively enables the operator to maintain a specific rate across a much wider speed range while delivering a consistent droplet size within the nozzle pressure range.

Think of 3TS as a three-step gearbox. Each nozzle type has an operating pressure band for a given droplet size. As the first nozzle reaches the top of the pressure band it switches off and the next larger size nozzle switches on. When that nozzle reaches the top of that pressure band the first nozzle will switch on again, effectively giving three operating bands.

The table below shows the pressure variations of two common nozzles, 015 & 02 operating at 70 l/ha through their respective pressure ranges from 7 km/h through to 27 km/h.

3TS Pro – the ultimate control and flexibility without leaving the cab.

The 3TS Pro is essentially our 3TS system with an added nozzle to give a wider range of operating spray rates without manually changing jets.

If you are constantly changing rates but want to keep your speed consistent, the 3TS Pro is for you.

For example, you may want to apply 70l/ha with your combination of 015 & 02 nozzles to give the overall capacity of an 035 nozzle (as per 3TS chart shown), then increase your rate in certain parts of the crop, other paddocks or even in the application of fertilisers.

In most cases, you would need to slow down to increase the rate as you would previously exceed the nozzle pressure range. With the additional nozzle, the 3TS Pro will automatically select the best nozzle combinations for your speed and rate while maintaining the working pressure range of the nozzles.

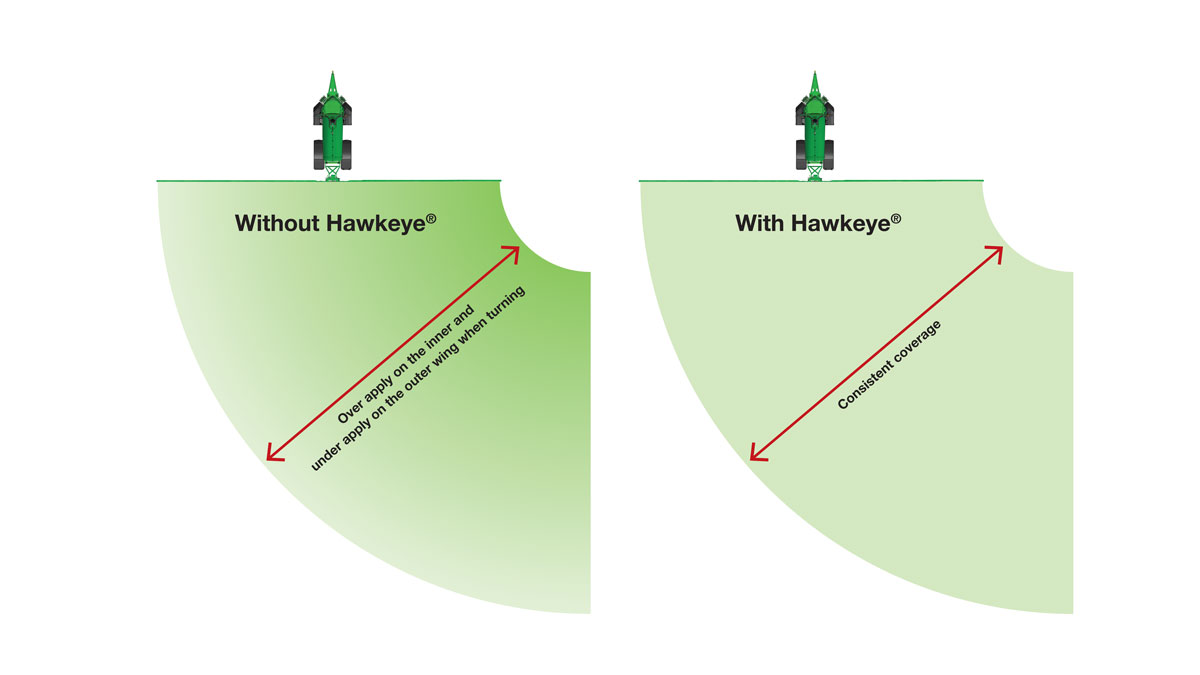

- New to the Pro is the option to fit a Pulse Width Modulated (PWM) spray system. The system known as Hawkeye 2.0 is the second generation PWM and offers significant benefits over the previous model. Goldacres will be offering the PWM on 36m and 48m booms with nozzle spacing at 250mm or 500mm.

- Nozzle by nozzle turn compensation.

- Each nozzle features its own microprocessor which can perform diagnostic functions.

- Up to 16 virtual sections or individual nozzle control (Optional).

- The system runs at 10Hz with a blended pulse application.

- System controlled through the ISO BUS terminal.

AutoBoom XRT – Radar boom height sensing technology

- The height sensors are radar-based and enable a large height measurement range, they can detect both ground and crop canopy and are less affected by spray drift, dust and mud. The sensors are also very compact, allowing easy fitment along the boom.

- The Raven XRT system uses sensors to monitor the sprayer chassis rate of roll, the boom centre position relative to the chassis as well as boom wing tilt angle. These sensors allow the computer to predict how the boom will react well before the radar sensors even see the change in boom height. The end result is a more stable boom in uneven terrain.

- The centre section has variable rate dampeners to stiffen the centre section roll action which allows the boom wing tilts to be operated much faster without affecting the boom stability.

- The XRT operating status is displayed on the G-Hub internal screen.

| Prairie Pro 5000L | Prairie Pro 6500L | Prairie Pro 8500L | Prairie Pro 10,000L | ||

|---|---|---|---|---|---|

| Chassis: Fully welded modular construction | 200 x 100 x 9mm RHS with stepped in rear section | 200 x 100 x 9mm RHS with stepped in rear section | 250 x 150 x 9mm RHS | 250 x 150 x 9mm RHS | |

| Stub axle size | 90mm | 110mm | 150mm | ||

| Airbag suspension | Standard | Standard | Standard | Standard | |

| Axle track width | 2000mm | Standard | Standard | – | – |

| 2200mm | – | – | Standard | Standard | |

| 3000mm | Optional (other widths on request) | Optional (other widths on request) | Optional (other widths on request) | Optional (other widths on request) | |

| Brakes | Optional | Optional | Optional | Standard | |

| Wheel & Tyres | 18.4 x 38 | Standard | Standard | – | – |

| 520/85R42 | Optional | Optional | Standard | – | |

| 520/85R46 | – | – | Optional | – | |

| 480/80R46 | Optional | Optional | Optional | – | |

| 480/80R50 | – | Optional | Optional | Optional | |

| 710/70R42 | – | – | Optional | Standard | |

| Poly Mudguards (fully length) | Standard | Standard | Standard | Standard | |

| Drawbar connection | Swivel tow ring feeder style drawbar connection | Standard | Standard | Standard | Standard |

| 80mm ball type drawbar connection | Optional | Optional | Optional | Optional | |

| Parking Jack | Manual | Standard | Standard | – | – |

| Hydraulic | Optional | Optional | Standard | Standard | |

| Rate controller | RCM ISOBUS control | Standard | Standard | Standard | Standard |

| G-Hub | Internal Aux Keypad with 5” external screen | Standard | Standard | Standard | Standard |

| 12” internal screen with rear view camera kit | Optional | Optional | Optional | Optional | |

| Spray pump | 260 l/min diaphragm with hydraulic drive | Standard | Standard | Standard | Standard |

| 400 l/min multistage centrifugal | Optional | Optional | Optional | Optional | |

| Agitation pump | – | – | Optional | Standard | |

| Filtration | 1 x suction (per pump) 1 x self cleaning pressure |

Standard | Standard | Standard | Standard |

| Nozzle filters | Standard | Standard | Standard | Standard | |

| Water transfer (filling) | 3” integrated fill point with electric shut off | Standard | Standard | Standard | Standard |

| 3” hydraulic pump high flow | Optional | Optional | Optional | Optional | |

| Chemical transfer | Chemical venturi probe | Standard | Standard | Standard | Standard |

| Air powered chemical transfer pump | Optional | Optional | Optional | Optional | |

| Micromatic rinse socket | Optional | Optional | Optional | Optional | |

| Electric switching between main tank and rinse tank suction | Standard | Standard | Standard | Standard | |

| High capacity hydraulic drive oil filled air compressor | Standard | Standard | Standard | Standard | |

| Washdown gun | Standard | Standard | Standard | Standard | |

| Main tank drain | 3” remote operated with cam lock fitting | Standard | Standard | Standard | Standard |

| Main tank capacity | 5000L | 6500L | 8500L | 10,000L | |

| Rinse water tank capacity | 500L | 500L | 800L | 800L | |

| Rotating tank rinse nozzles | Standard (twin) | Standard (twin) | Standard (triple) | Standard (triple) | |

| Boom type & size | 24m TriTech RivX | Optional | Optional | – | – |

| 28m TriTech RivX | Optional | Optional | – | – | |

| 30m TriTech RivX | Optional | Optional | Optional | – | |

| 36m TriTech RivX | – | Optional | Optional | Optional | |

| 48m TriTech V | – | – | Optional | Optional | |

| Boom breakaway | Outer wing break back plus 3D mechanism on last section | Standard | Standard | Standard | Standard |

| Blue boom lights | Standard | Standard | Standard | Standard | |

| Hydraulic yaw | Standard | Standard | Standard | Standard | |

| Individual wing tilt | Standard | Standard | Standard | Standard | |

| Bi-fold outer boom wing (Tri-fold on 48m) | Standard | Standard | Standard | Standard | |

| Radar boom level system with 5 sensors | 24-36m TriTech RivX boom | Optional | Optional | Optional | Optional |

| 48m TriTech V Series boom | – | – | Standard | Standard | |

| RapidFire with RapidFlow 500mm spacing | Standard | Standard | Standard | Standard | |

| 3TS RapidFire with RapidFlow | Optional | Optional | Optional | Optional | |

| 3TS Pro | Optional | Optional | Optional | Optional | |

| Hawkeye PWM system, turn compensation, 16 sections, 250mm spacing | – | Optional (36m only) | Optional (36-48m only) | Optional (36-48m only) | |

| Hawkeye PWM system, turn compensation, 16 sections, 500mm spacing | – | Optional (36m only) | Optional (36-48m only) | Optional (36-48m only) | |

| Hawkeye unlock for individual nozzle control | Optional | Optional | Optional | Optional | |

| Trijets | Optional | Optional | Optional | Optional | |

| 500mm broadacre plumbing | Standard | Standard | Standard | Standard | |

| 500mm rowcrop plumbing | Optional | Optional | Optional | Optional | |

| Boom plumbed in 10 sections | Standard | Standard | Standard | Standard | |

| Boom plumbed in 16 sections | Optional | Optional | Optional (Standard with 48m) | Optional (Standard with 48m) | |

| Double sided electric operated fenceline nozzles | Standard | Standard | Standard | Standard | |

| Remote grease nipple bank | Standard | Standard | Standard | Standard | |

| 60L Chemical induction hopper | Standard | Standard | Standard | Standard | |

| Dimensions | 3750 H x 3490 W x 8960mm L 30m TriTech RivX boom |

3750 H x 3490 W x 9560mm L 36m TriTech RivX boom |

4550 H x 3490 W x 9900mm L 36m TriTech RivX boom |

4550 H x 4300 W x 9900mm L 48m TriTech RivX boom |

|

- Prairie Pro Series 2 - RivX TriTech Boom

- Prairie Pro Series 2 - 48m TriTech V Series Boom

- Customer Testimonial

- Induction Hopper - How to

- Fast Fill - How to

- Prairie Pro 1048