Australia’s only true green on green spot spraying system available.

Weedetect® is a market leading weed detection and spraying system that utilises cutting-edge artificial intelligence and camera technology to isolate weeds within crop and fallow situations — vastly reducing herbicide input costs.

Spraying Benefits

+

With the Bilberry system, a grower can be sure that they have the right dose, in the right place, at the right time.

- Up to 90% chemical savings: Cut your chemical expenses by spraying only where weeds are.

- Increase knowledge of your paddock: Generate and store weed maps of each spray to better understand your paddock.

- Resistance management: Use more effective chemicals at a higher dose for better weed control.

- Sustainable farming: Prolong herbicide life on your farm while helping the environment.

- Reduce crop damage: Increase yield by minimising unnecessary crop injury.

- Spray fast: 20 km/h average speed and up to 48-metre boom.

- Reduce filling time: By spraying 10× less, you’ll also fill up 10× less.

- Reduce chemical exposure: By filling less, you’ll be less exposed to chemicals.

Sprayer Compatibility

+

Factory Fitted: The Weedetect system can be fitted to your new Goldacres:

- G4 Crop Cruiser- Series 2

- G6 Crop Cruiser- Series 2

- G8 Crop Cruiser- Series 3

- G8 Super Cruiser

- Advanced Camera Technology – Captures 16 images per second and feeds them directly to the computing module for real-time processing

- Precision Application – Automatically calculates exact timing and duration of nozzle opening to deliver lethal herbicide doses to targeted weeds

- Simple Operation – Clean, user-friendly interface where growers select the appropriate algorithm for their crop and operate at speeds up to 25km/hr

- AI-Powered Weed Detection – Uses artificial intelligence algorithms developed from tens of thousands of images for each specific application

- Smart Integration – In-cab screen communicates with nozzle controllers while receiving constant updates from GPS and other machine systems

- Optimal Performance Requirements – Cameras work best at 1.5 metres from target, making boom height control essential for accurate operation

Why spot spraying?

+

Traditionally, herbicides are applied to a paddock in a blanket spray in an effort to reduce weed numbers, and ensure that there are minimal survivors which decreases the chance of seed set. In fallow or summer spraying situations, this has historically been achieved through blanket spraying broad spectrum or non-selective herbicides to eliminate all plants present.

This can be done for many reasons, including:

- Conservation of moisture for the following crop

- Reduce the green bridge for potential disease carryover

- Machinery trafficability and less blockages at seeding time

Spot spraying is the alternate way in which weeds in fallow and crop situations can be managed. This reduces the cost of herbicides, saves water, aids in the reduction of herbicide resistance by being able to deploy stronger chemicals on a smaller scale and saves time due to less filling up of boomsprays.

Historically, fallow spot spraying has been achieved through the use of chlorophyll sensors to identify weeds on bare paddocks, or green plant matter on soil (Green on Brown). This technology has been available for many years with good results, and has reduced the herbicide use of non-crop situations up to 90%.

This is how it works

+

- Measure the reflectance of green plants (using near infrared wavelengths) which triggers the weed to be sprayed

- Can be used day and night as they have their own light source

- Can reduce herbicide application by 80 to 90% (depending on density of weeds)

- By reducing area sprayed it also reduces number of tank fills required (fewer litres of spray mix per ha)

- Boom height control is critical to ensure adequate coverage of weeds

- Coverage is affected by strong winds which moves the spray pattern away from the targeted weed

*Refer to below list of commercial applications

Can we improve this technology?

+

- Advanced AI capabilities – No longer limited to chlorophyll sensors; cameras can now distinguish weeds from crops (“Green on Green”)* technology

- Industry-wide development – Start-ups, corporations, and universities are creating similar systems using AI with RGB or hyperspectral cameras

*Refer to below list of commercial applications.

How does AI work?

+

- Deep learning technology – Uses computer vision to recognize objects in complex images with high variability

- Three key enablers:

- Graphics processing units (GPUs) for computing power

- Big data sets for training

- Complex neural network algorithms

- Brain-inspired design – Uses deep neural networks that mimic human brain function with supervised or unsupervised learning

System limitations

+

- Camera systems are affected by high stubble loads, crop shading, and canopy closure – a limitation shared by all optical sprayers (GoB or GoG)

- Camera systems will never achieve 100% hit rate – a two spray strategy is highly recommended

- If cameras cannot see weeds, they cannot spray them

- Night spraying is green on brown compatible only

- Setting realistic expectations with potential users is paramount

- Success comes from happy users whose expectations are met – underpromise and overdeliver

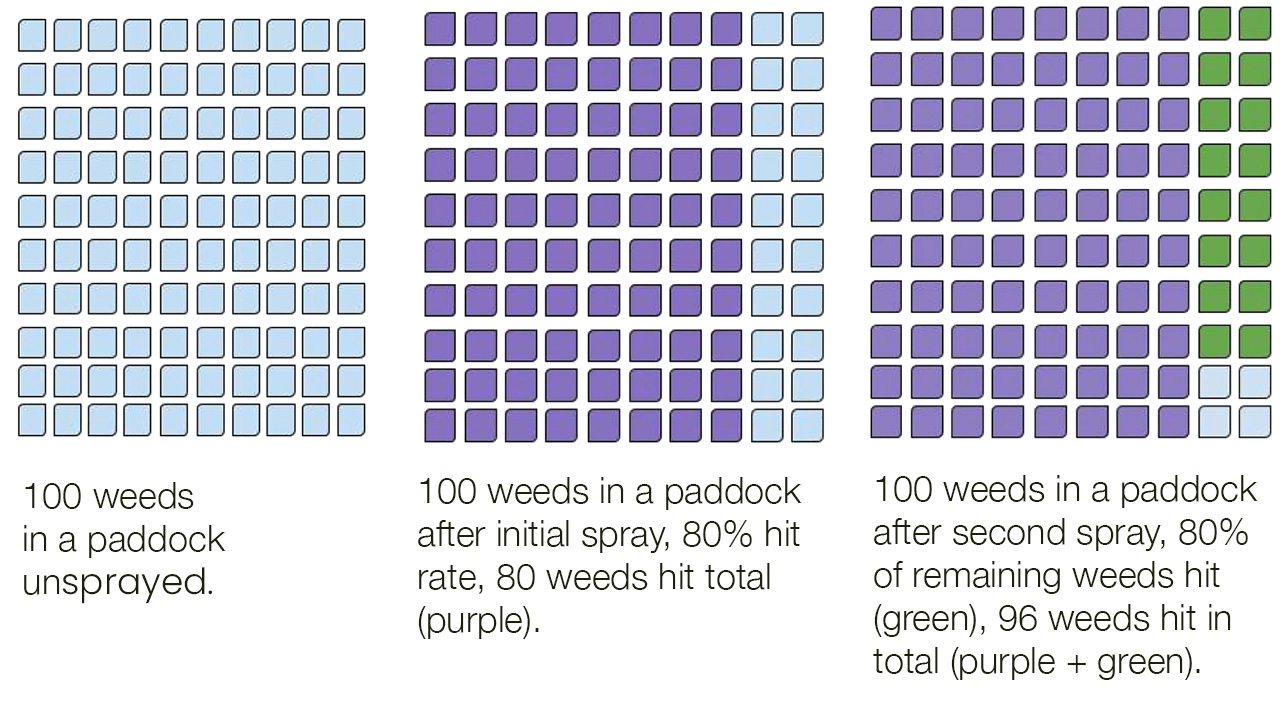

2 spray strategy

+

Two Spray Strategy Benefits

- A two-spray approach ensures minimal weed survivors by targeting later germinating weeds

- Second spray timing catches escapees from the first application, significantly improving overall control

Hit Rate Calculations

- Individual spray hit rate of 80% = 96% total control when combined

- Individual spray hit rate of 90% = 99% total control when combined

- Individual spray hit rate of 60% = 84% total control when combined

System Integration

- Bilberry camera system is an additional tool for integrated weed management

- Works alongside double knocks, harvest weed seed management, and other Weedsmart ‘Big 6’ components

- Confident the system will achieve 80%+ hit rates per application

The artificial intelligence that we have previously mentioned needs to be able to see and compute images to identify the weeds in real time. To do this, the system requires eyes, a brain, and a voice.

Cameras

+

12 high-definition video cameras are positioned every three metres, ten along the boom, and two mounted on either side of the front of the chassis.

12 high-definition video cameras are positioned every three metres, ten along the boom, and two mounted on either side of the front of the chassis.

The cameras are constantly looking 4 metres ahead, detecting weed shapes (not chlorophyll) this enables the system to detect weeds in crop. A real game-changer for using substantially less chemical all year round.

As the system relies on accurate information, the height of the boom is paramount to its performance. The cameras work most accurately at 1.5 metres from the target; therefore, a height controller is recommended for camera fitted sprayers.

Specifications:

- G6MP RGB (red green blue) camera

- Input voltage DC : 12-24V

- Weight: 0.7 kg

- Prairie Auto

- IP67 rating case

- External connector: 1x Hybrid cable

Calculation module

+

Role: An artificial intelligence computer module that is capable of computing large amounts of data, in real time, detecting the weeds through patented algorithms and determining the correct location, time, and duration for a nozzle to trigger to spray the individual weed.

Specifications:

- Input voltage DC: 24V

- Power consumption max: ~25W

- Weight: 1.5 kg

- IP67 rating case

- Connectors: 2x Hybrid

- 1 calculation module per four cameras

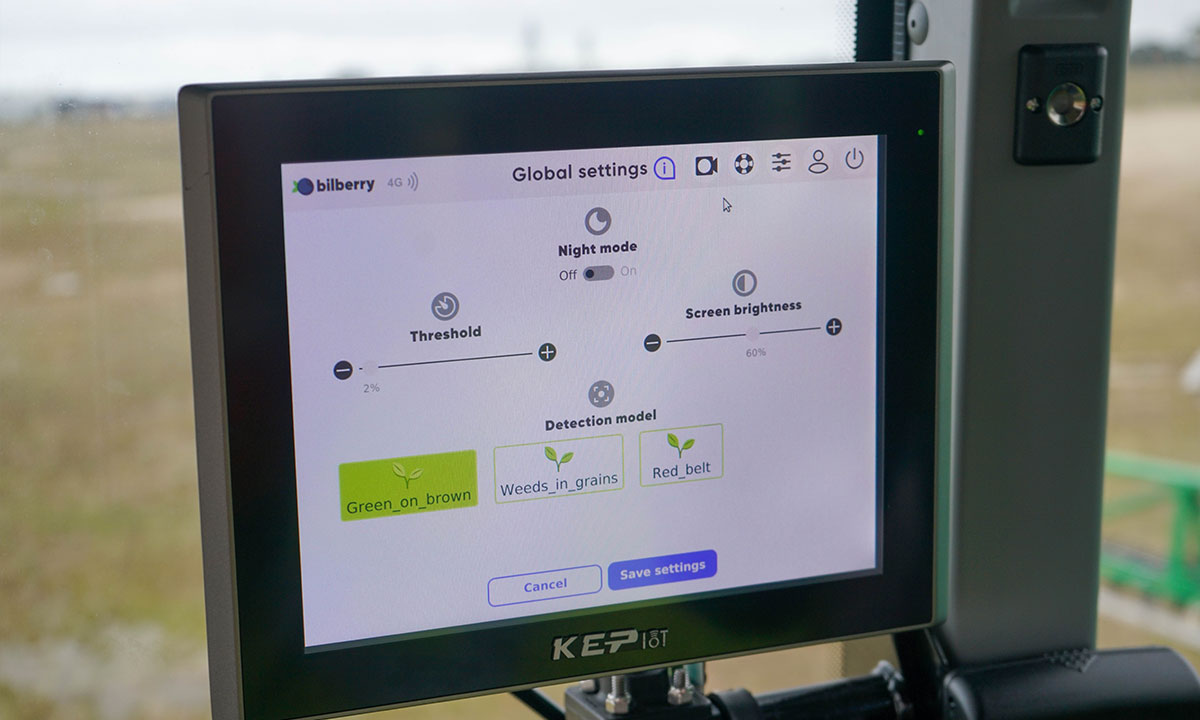

Display Screen

+

A screen is mounted in the cab of the machine to interpret the signals from the AI computing module, interact with the GPS and nozzle controller, allow user input to change algorithms, sensitivities to weeds etc.

A screen is mounted in the cab of the machine to interpret the signals from the AI computing module, interact with the GPS and nozzle controller, allow user input to change algorithms, sensitivities to weeds etc.

Specifications:

- Input voltage DC: 12-36V

- Power consumption: 14 W

- Weight: 2.8 kg

- 1 camera every 3 metres

Modem

+

Connectivity with Bilberry for software updates, mapping features, remote maintenance and troubleshooting. Not needed for operational use of the system, as the Bilberry system is designed to work independently offline at all times. The Bilberry system is also designed to connect seamlessly with any pre-existing modem.

Switch

+

Role: Connect the calculation modules to the console (over ethernet links), provide power to the calculation modules and cameras

Specifications:

- Passive element: Gather & Dispatch (power / data)

- Input voltage DC: 24V

- Power consumption max: ~10W

- Weight: 2.3 kg

- IP67 rating case

- Connectors:

– 8x Hybrid cable

– 1x automotive Power Connector

Cabling

+

Custom made hybrid cables have been designed and manufactured specifically for the Bilberry system, keeping in mind the harsh Australian conditions that sprayers endure such as dust, sun, uneven terrain etc. These cables allow the cameras and the modules to relay information with both the screen and each other, while also providing power for the cameras and computing modules. This integrated power reduces the need for separate cables to be run and streamlines the weight distribution and cable management for the install and correct ongoing operation.

Light Bars

+

Only used during Green on Brown spraying. The optional LED light bar is fitted below every camera, and the beam is angled to illuminate 4 meters in front of the boom at the point that the camera detects the weeds in crop. The light bar is essential if you are planning to spray in low light or night-time spraying.

| Crop | Weed Control Options |

|---|---|

| Cereals | Broadleaf |

| Canola | Grass |

| Lupin | Broadleaf, Grass, Blue Lupin, Blue Lupin and Broadleaf |

| Lentils | Broadleaf, Grass, All Weeds, Vetch, Broadleaf and Vetch |

| Chickpeas | Broadleaf, Grass, All Weeds, Broadleaf and Vetch |

| Sorghum | Broadleaf, Grass, All Weeds |

| Cotton | Broadleaf, Grass, All Weeds |

| General | Green on Brown (Day and Night) |

| Features | |

|---|---|

| Cameras | 36m system – 12 x high-definition cameras |

| Light Bars | 12 x LED lights (Optional) |

| Boom widths | up to 36m |

| Self-propelled sprayers | The system can also be fitted to existing G4, G6 & G8 sprayers that feature a centrifugal pump.

A centrifugal pump is needed to supply the system with constant flow. |

| Trailed sprayers | At this stage the weededect system is not available to be fitted to trailing sprayers.

As the cameras are looking 4 meters ahead at all times to detect weeds the articulation of the tractor and sprayer do not support the accuracy the system requires. |

| Pricing | The weedetect system can be done per hectare, annually or for green on brown as a permanent basis.There are no ongoing fees. |

- Jayden Warr - Weedetect

- Broden Holland - Weedetect

- Kyle Carson - Weedetect

- Weedetect - Powered by Bilberry

- Green-on-Green Spot Spraying - Broad-leaf Weeds in Cereals

- Grass Detected in Lupin Crop Using Bilberry's Green on Green Technology