Register your interest

The Goldacres Prairie Auto represents a cutting-edge, autonomous weed detection platform specifically engineered to minimise chemical usage and amplify the efficiency of your spraying program.

Utilising innovative weed detection camera technology, it significantly reduces chemical consumption compared to indiscriminate spraying. The ability to detect weeds within the crop is a revolutionary advancement for year-round spraying programs.

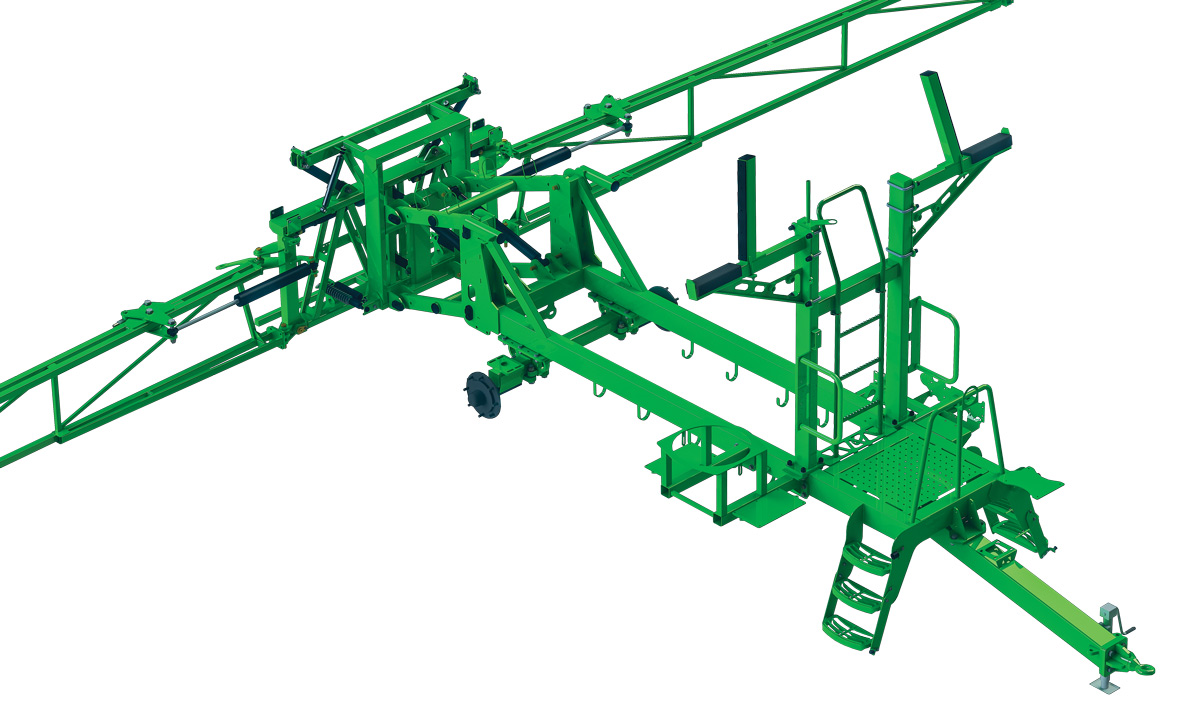

Equipped with a 2500L tank, optional 600L transfer tank, and a Delta suspended boom available in 12, 18, or 24m widths, the Prairie Auto also features WeeDetect spot spraying technology. This technology facilitates targeted spraying, differentiating between green on green (weeds in crop) or green on brown scenarios, employing individual nozzle control for precise application.

The Prairie Auto serves as a comprehensive spraying solution, seamlessly integrated with an Australian made Swarmfarm autonomous robot. When paired with Swarmfarm robot, this system empowers users to conduct spraying operations with significantly reduced chemical usage, optimal spraying conditions, and the flexibility of 24/7 operation—all without the need for a physical operator. Swarmfarm robots are not purchased through Goldacres.

The small frame Prairie Special design incorporates many elements to ensure maximum strength, longevity and performance. Features such as fully bushed pivot points, precision laser cut components and the best corrosion proof paint system, fully welded in rotating positional jigs ensures accuracy, repeatability and quality all combined with the experience gained with thousands of sprayers in the field.

- Chassis. Manufactured from high strength heavy walled 125x75x6mm RHS to minimise flexing and provide a stable platform for boom mounting. The rear chassis section features an integrated boom and tank support (3000L version only). Long wheel base (axle to drawbar) provides excellent boom yaw stability and reduces sideways pushing forces at the tractor.

- Drawbar pull. Single 150mm square drawbar section allows tighter headland turning. Full 360-degree swivel forged tow eye ensures maximum articulation between sprayer and tractor.

- Walk through platform. Access the main tank easily and safely from either side of the sprayer. No need to walk around the sprayer or tractor to access the other side. Open foot treads provide safe access to platform in muddy conditions. Lower portion of treads fold up out of the way when not in use.

- Boom rest. The adjustable height boom rests with rubber supports provide a soft contact point for the boom wings, minimising the chance for damage.

- Boom parallelogram lift. The mechanism provides boom height adjustment as well as the vertical suspension.

- Delta boom centre section. Using lightweight trussing techniques the boom centre section is light yet extremely strong. All high load pivot points are greaseable, ensuring a long service life and optimum boom suspension performance.

- Paint and anti-corrosion system. All major components are fully grit blasted using a fractured steel shot, essential for excellent paint adherence. The bare steel components are then treated using a high build filler primer which flattens the blasted surface. All un-welded joints are seam sealed then top coated using Goldacres’ exclusive chemical resistant paint formula. Finally all components are baked in a high temperature oven until fully cured.

All zinc plated pins and bolts on the boom are coated with rust preventative G15, which adds another level of corrosion protection. - Full modular construction technique allows many options to be easily added at the time of build or at a later date as required. Dealer Fit Options (DFO) can be retrofitted without the need for welding or drilling existing components.

| Feature | Description | |

|---|---|---|

| Product Tank | 2500L | |

| Chemical Tank | 600L tank mounted to robot with auto chemical transfer | |

| Axles | 3 meter wheel centres | |

| Booms | 12, 18 or 24m Delta booms | |

| 250mm nozzle spacing | ||

| Boom Recirculation (RapidFlow) | ||

| Precision Ag | Weedetect – Green on Brown spot spraying with Green on Green option (individual nozzle control) | |

| Weedetect – Night spraying lights | ||

| Auto boom height control | ||

- Swarmbot Robitics

- Prairie Auto

- Prairie Auto - Explainer