Strength, Stability, Reliability & Control

The new generation TriTech V Series boom range is designed for operators who demand the utmost performance, reliability and control. Time and time again the TriTech boom has been named No.1 for boom stability*, which at the end of the day, results in a superior spray result.

Features such as hydraulic yaw which precisely controls the forwards and backwards movement of the boom wings to minimise the under and over applying of chemical is now standard on all widths.

Hydraulic outer wing fold with dampened over centre spring break back maintains perfect outer to inner boom alignment, plus with the added safety feature of a break back mechanism.

The strategically placed centre section suspension links help isolate the sprayer chassis movement over rough terrain. Combined with the tuned damping characteristics allows precise roll control enabling an optimal and consistent nozzle height to be maintained, even without the use of electronic height control systems**.

All TriTech booms are constructed using lightweight trussing techniques, which allows for a stronger design without weight, the enemy of boom agility.

*Kondinin group’s Farming Ahead magazine 2012 and 2014 **Height control systems may be required in some extreme situations

Why is boom ride and stability so important?

A boom which bounces, sways or yaws deposits chemical unevenly on the target. This can result in weed escapes and may even contribute to resistant weeds.

The Goldacres TriTech suspension system has been developed to provide you with the best boom ride possible and assist in an accurate application. Working in conjunction with the chassis airbags three-way suspension that works to reduce boom pitch, roll and yaw – the three enemies of accurate application. A combination of springs and shock absorbers, as well hydraulic cylinders and accumulators all work together to provide the best boom ride possible. The TriTech suspension system has contributed to Goldacres consistently having the best boom ride when measured against

competitor machines.

Yaw

Hydraulic yaw – Two opposing hydraulic cylinders are mechanically connected together either side of the pivoting boom centre section.

As the centre yaws one cylinder is retracted, the other is extended.

This results in oil movement which compresses in a nitrogen charged accumulator. The result is precise boom yaw control.

Roll

Delta links – The key to the superior boom ride is the strategically placed delta links. In all there are four links. Each link features spherical ball ends which allow the centre to move in all directions.

Roll centre point – The roll centre point is the location at which the boom pivots around, both in roll & yaw.

Roll dampeners – Reduces high frequency oscillation of the boom roll.

Many farms and crop varieties have different requirements when it comes to chemical application systems.

The new V Series TriTech boom utilities a five chord layout on the inner wing with the main boom folding pivot points above the nozzles. This layout allows virtually any nozzle configuration and spacing width to be achieved.

Goldacres are able to configure the boom to include single, double, clock face 3-5 nozzles bodies, droppers and high volume air sleeve systems just to name a few.

Wide choice of nozzles available from leading brands such as TeeJet and Lechler.

RapidFire and RapidFlow nozzle switching technology

Goldacres pioneered the use of pneumatic nozzle switching technology and boom recirculation in Australia more than a decade ago. In that time this technology has become the standard method for reducing chemical waste.

The pneumatic nozzle switching replaces traditional boom section valves to control water flow to the nozzles, with the trend moving to wider booms in conjunction with a greater number of spray sections meant that the traditional system simply became “ too busy“ with the number of hoses on the boom required. The Goldacres RapdiFire and RapidFlow system uses a single common feed spray line with the nozzles switching on and off using a number of small pneumatic hoses.

The result is significantly reduced amount of spray hoses, reduced volume of chemical in the boom lines, quick on / off times for the nozzle, easy to reconfigure section spray widths and number of sections and of course the ability to flush the spray line back to tank without the need to physically spray on the ground.

Nozzle technology has advanced in leaps and bounds over the years and a strong emphasis on drift control has influenced many nozzle designs,

including air induction (AI) technology

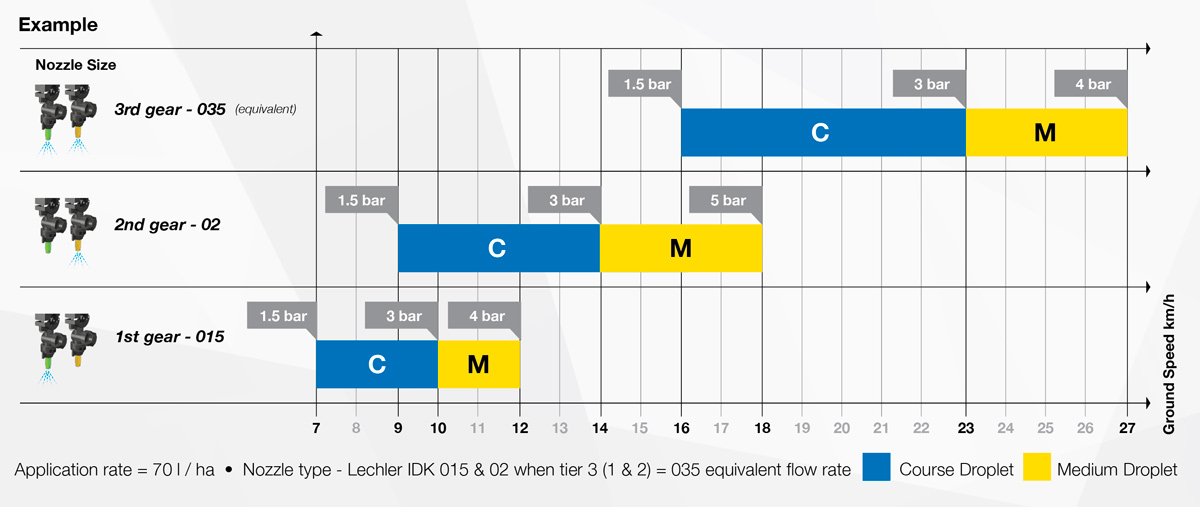

The spray nozzles operating pressure range and size determine the application rate and speed band at which the driver must adhere to. This band is usually quite narrow. To overcome this Goldacres offer a 3 tier system (3TS) which effectively gives the driver a much wider operating band whilst still maintaining optimum droplet size. Think of 3TS as a three step gearbox. Each nozzle type has an operating pressure band for a given droplet size. As the first nozzle reaches the top of the pressure band it switches off and the next larger size nozzle switches on. When that nozzle reaches the top of that pressure band the first nozzle will switch on again, effectively giving three operating bands.

| Sprayer | 24m | 28m | 30m | 36m | 42m | 48m |

|---|---|---|---|---|---|---|

| Prairie Pro (8500L only) | ✓ | |||||

| G4V Crop Cruiser | ✓ | ✓ | ✓ | ✓ | ||

| G6 Crop Cruiser | ✓ | |||||

| G8 Super Cruiser | ✓ | ✓ | ✓ |